Jul 21, 2021

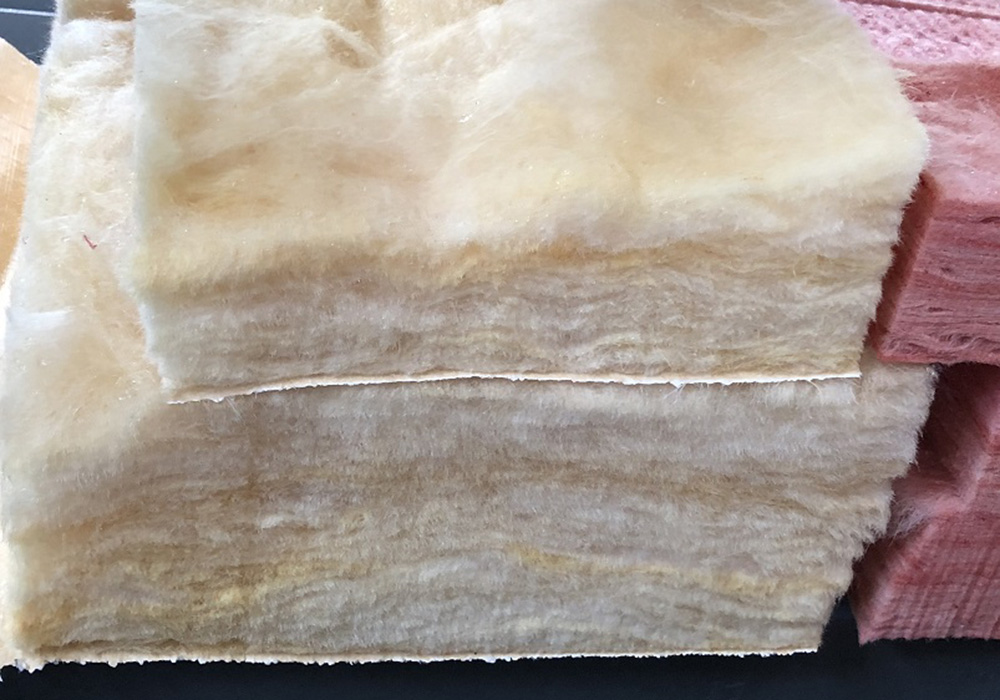

Rock wool consists of 60% diabase, 20% limestone and 20% coke. After being melted in a high-temperature furnace at 1500~2000℃, it is sprayed into filaments with a diameter of 0.005 mm, and then pressed the filaments into a plate with a density of 80~1000 kg/m³.

High-pressure water jet cutting is the main processing for cutting rock wool. High-pressure water is used to cut rock wool at high speed to meet customers' high-efficiency requirements. With the improvement of customers’ requirements and the need to meet the cutting efficiency, most water jets are combined with the assembly lines to cut rock wool.

High-pressure water jet cutting is the main processing for cutting rock wool. High-pressure water is used to cut rock wool at high speed to meet customers' high-efficiency requirements. With the improvement of customers’ requirements and the need to meet the cutting efficiency, most water jets are combined with the assembly lines to cut rock wool.

See the following pictures as below:

1. The rock wool is fixed on the special tooling, and the water jet cutting head is calibrated to ensure the position accuracy and precision when cutting.

2. The high-pressure pure water cutting head operates at a high speed of 50 m/min to cut 150 mm thick rock wool. For detailed cutting efficiency and cutting quality, see the following cutting video and cutting photos;

With the rapid development of the water jet industry, high-efficiency water jet cutting machine has been widely used in the rock wool industry.