Echion™ waterjet pumps

New Echion™ pumps

Designed and built to simplify service

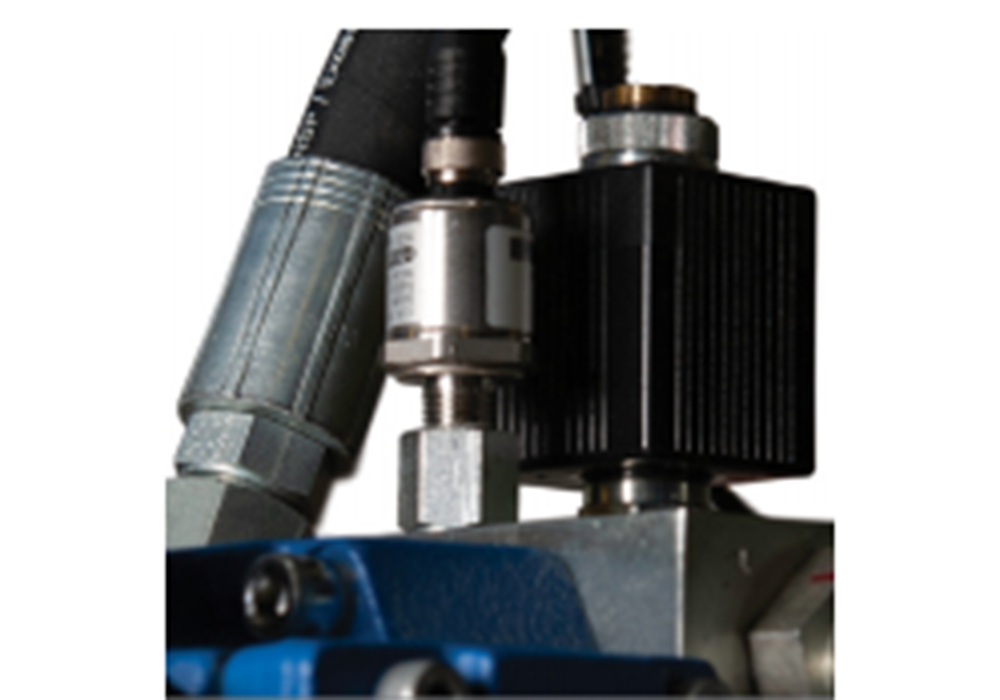

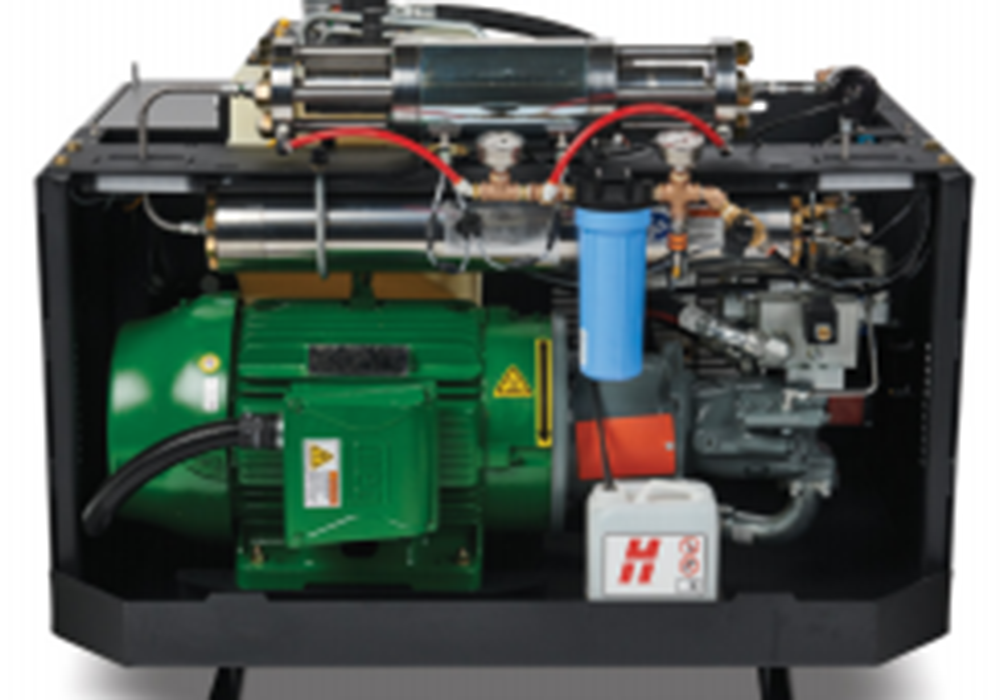

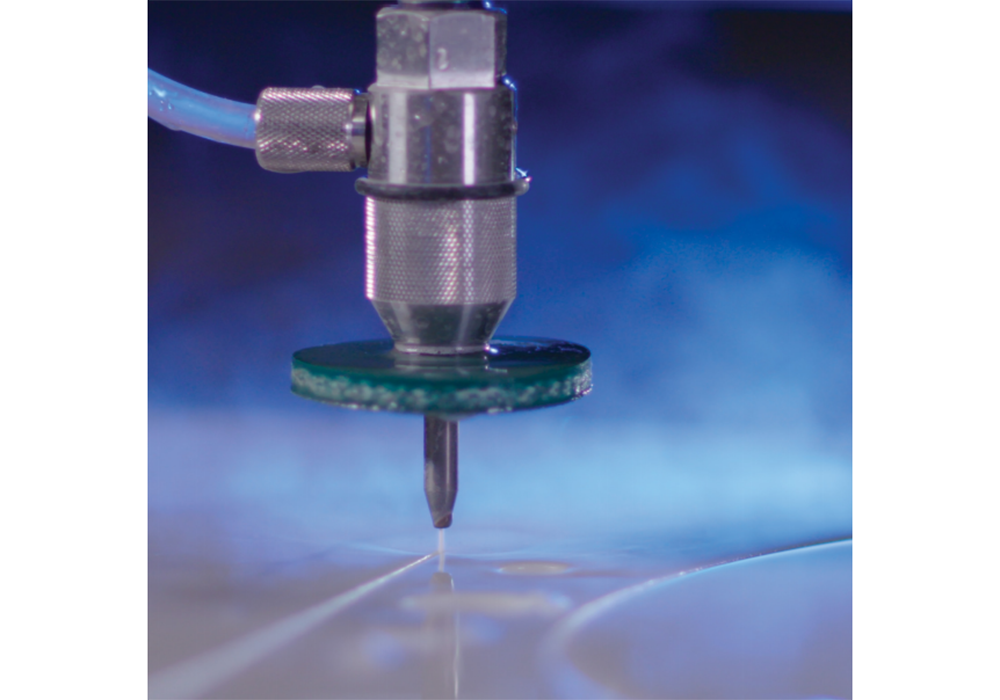

Echion pumps are the first waterjet pumps to incorporate cartridge seals that substantially reduce time to conduct maintenance. Equipped with standard features such as our next evolution of Advanced Intensifier Technology™ (AIT) and closed-loop proportional pressure control, our new pumps offer you consistent cut quality while ensuring trouble-free operation and reliability.

Designed and built to simplify service

Echion pumps are the first waterjet pumps to incorporate cartridge seals that substantially reduce time to conduct maintenance. Equipped with standard features such as our next evolution of Advanced Intensifier Technology™ (AIT) and closed-loop proportional pressure control, our new pumps offer you consistent cut quality while ensuring trouble-free operation and reliability.

Reduced maintenance time

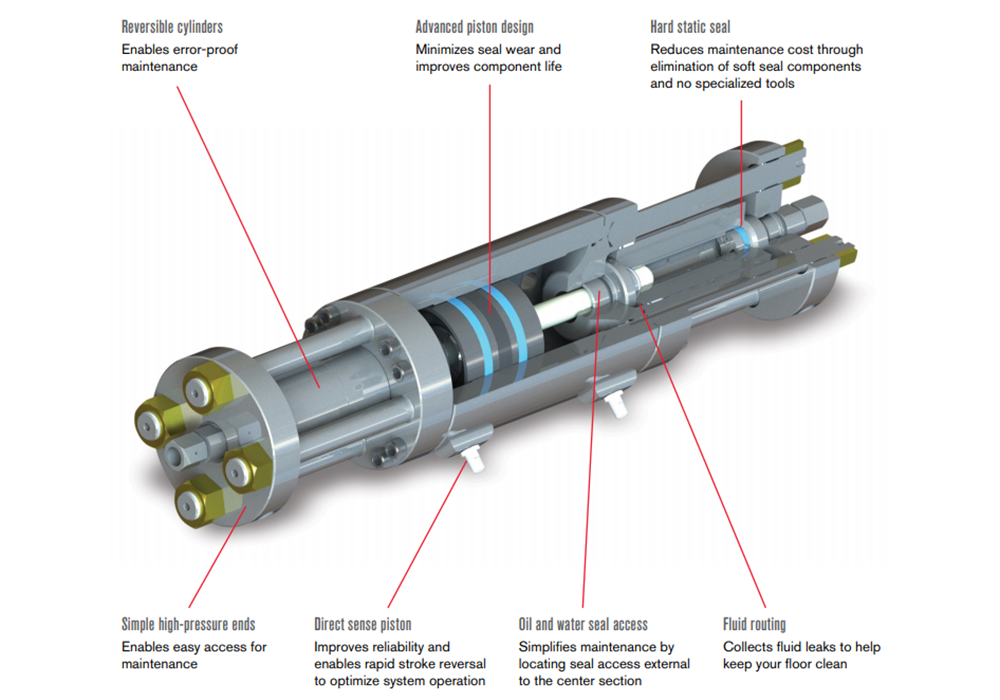

Echion pumps include the next evolution of Hypertherm’s Advanced Intensifier Technology. This technology eliminates soft, static high-pressure seals and incorporates industry-leading cartridge seal design, enabling rapid replacement of common consumables.

Increased performance

Standard on all Echion pumps, closed-loop proportional pressure control adjusts for ambient pressure and temperature, oil viscosity and hydraulic system wear parts, to deliver consistent quality at optimum cutting speeds.

Improved reliability and ease of service

Reduced footprint

The next evolution of Advanced Intensifier Technology simplifies system maintenance

Say goodbye to complicated seal repair. Hypertherm Echion™ pumps incorporate cartridge seals, enabling rapid replacement of common consumables, leading to quicker return to service. Add this to other key features of AIT and it’s easy to see why Hypertherm is an unstoppable force in waterjet!

Say goodbye to complicated seal repair. Hypertherm Echion™ pumps incorporate cartridge seals, enabling rapid replacement of common consumables, leading to quicker return to service. Add this to other key features of AIT and it’s easy to see why Hypertherm is an unstoppable force in waterjet!

System specifications

Choosing the right Echion™ pump for your application

|

Echion 15

|

Echion 30 | Echion 50 | |||||

| 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | 60 Hz | ||

| GENERAL | Maximum output | 1.1 lpm (0.3 gpm) | 2.3 lpm (0.6 gpm) | 3.8 lpm (1.0 gpm) | |||

| Maximum orifice | 0.18 mm (0.007") | 0.28 mm (0.011") | 0.35 mm (0.014") | ||||

| Output pressure | Adjustable to 4,100 bar (60,000 psi) | ||||||

| Pressure control | Closed loop proportional pressure control – standard equipment | ||||||

| Bleed down valve | Air-actuated | ||||||

| PUMP POWER | Motor power | 11.2 kW (15 HP) | 22.4 kW (30 HP) | 37.3 kW (50 HP) | ||||||

| Voltage | 400 V | 208–230 V | 460 V | 400 V | 208–230 V | 460 V | 400 V | 208–230 V | 460 V | |

| Full load | 23A | 45–41 A | 21 A | 44 A | 82–76 A | 38 A | 74 A | 136–124 A | 62 A | |

| Main breaker | 30A | 60 A | 30 A | 60 A | 100 A | 60 A | 100 A | 200 A | 100 A | |

|

Motor starter

(options if more than 1 listed)

|

Across-the-line |

Wye-Delta

Soft Start

|

Across-the-line |

Across-the-line

Soft Start

|

Wye-Delta

Soft Start

|

Wye-Delta |

Wye-Delta

Soft Start

|

|||

|

SPECIAL

FEATURES

|

Advanced Intensifier Technology | Included as standard equipment |

| Closed loop proportional pressure control | Included as standard equipment |

| PHYSICAL | Width | 1,090 mm (43") | ||

| Length | 1,350 mm (53") | |||

| Height | 1,010 mm (40") | |||

| Operating weight | 775 kg (1,700 lbs.) | 825 kg (1,850 lbs.) | 925 kg (2,050 lbs.) | |

| ACCESSORIES | Boost pump | Optional |

| Integrated air over oil cooling | Optional | |

| Bulkhead connection kit | Optional | |

| Metric conversion kit | Optional | |

| Pump mounted whip kit | Optional |

Core Component Options

Featuring a low noise, no pollution, high precision and high reliability

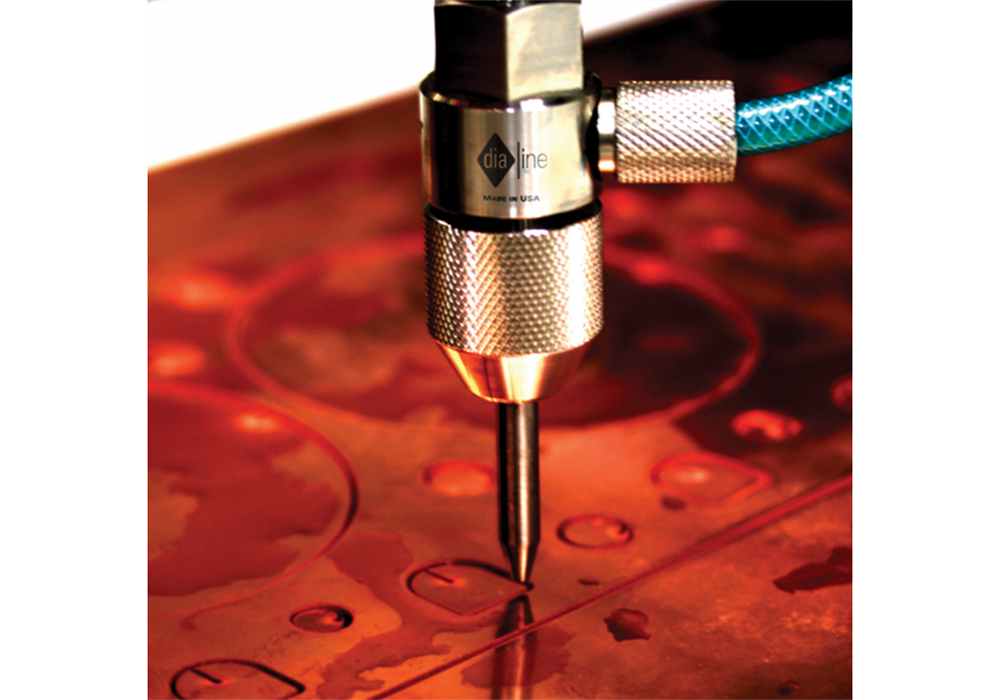

Max 5 cutting head

This Max 5 waterjet cutter can cut any angle within ±45°,it solves the traditional problem of water cutting inclination,and achieves 2D/3D cutting easily.

Dynamic 5 cutting head

Our Dynamic 5 water jet cutting machine can ensure the accuracy of vertical cutting section by compensating the 10°cutting angle,without reducing the cuttiong speed.

Multi-head

Double or multiple cutting heads can perform the cutting task with the same track at the same time to improve efficiency greatly.

This Max 5 waterjet cutter can cut any angle within ±45°,it solves the traditional problem of water cutting inclination,and achieves 2D/3D cutting easily.

Dynamic 5 cutting head

Our Dynamic 5 water jet cutting machine can ensure the accuracy of vertical cutting section by compensating the 10°cutting angle,without reducing the cuttiong speed.

Multi-head

Double or multiple cutting heads can perform the cutting task with the same track at the same time to improve efficiency greatly.

Unique design of this water jet cutting machine makes the installation and the maintenance easier.Stable working pressure to ensure the working efficiency.

1.YC pumps 40hp/50hp/100hp2.Hypertherm

Optional Functions