Wide scope of application

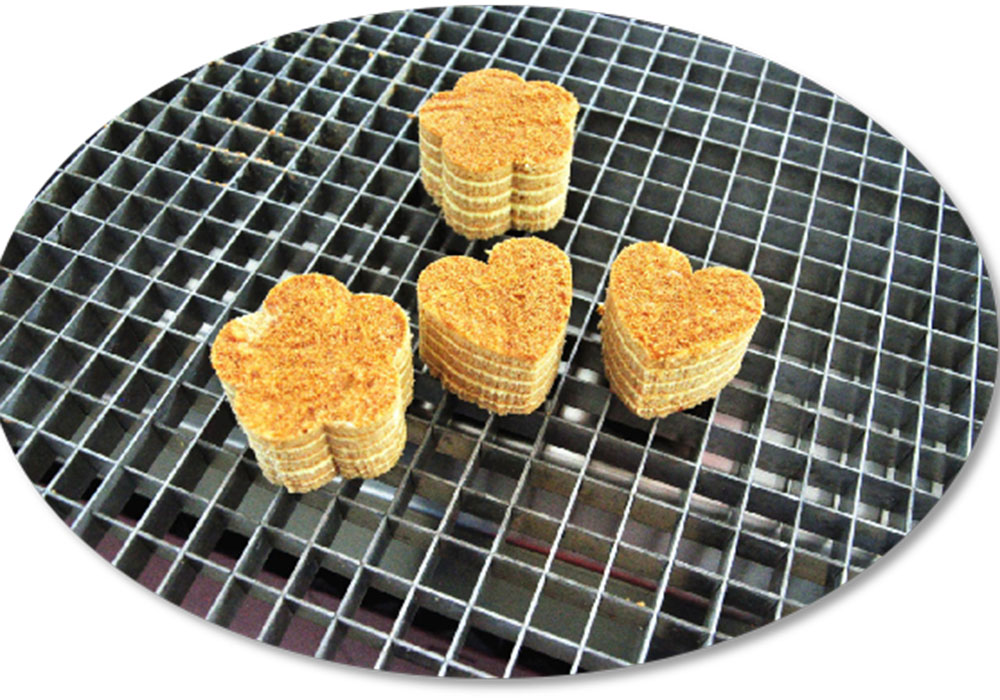

Water jet cutting can be used not only for all kinds of pastry, pizza, biscuits, moss, but also for meat, fish,vegetables and frozen food cutting etc.

Safety & Clean

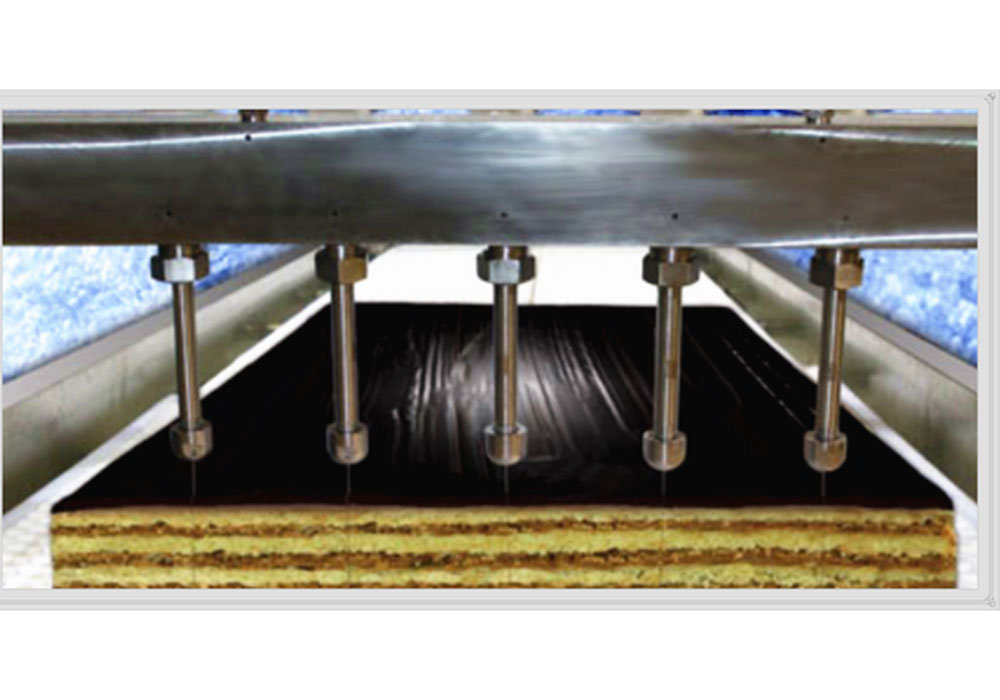

Cutting In the process of water cutting, food is only in contact with pure water, which avoids the risk of food contamination caused by traditional cutting tools.,It will not maake heat and add any chemicals. Hygiene is unmatched in the cutting process. typically the size of the stream is a width of a human hair at speeds up to 900m per second. This small kerf width is so thin that food will not be compressed or washed out. No need for mold,

Easy Operating

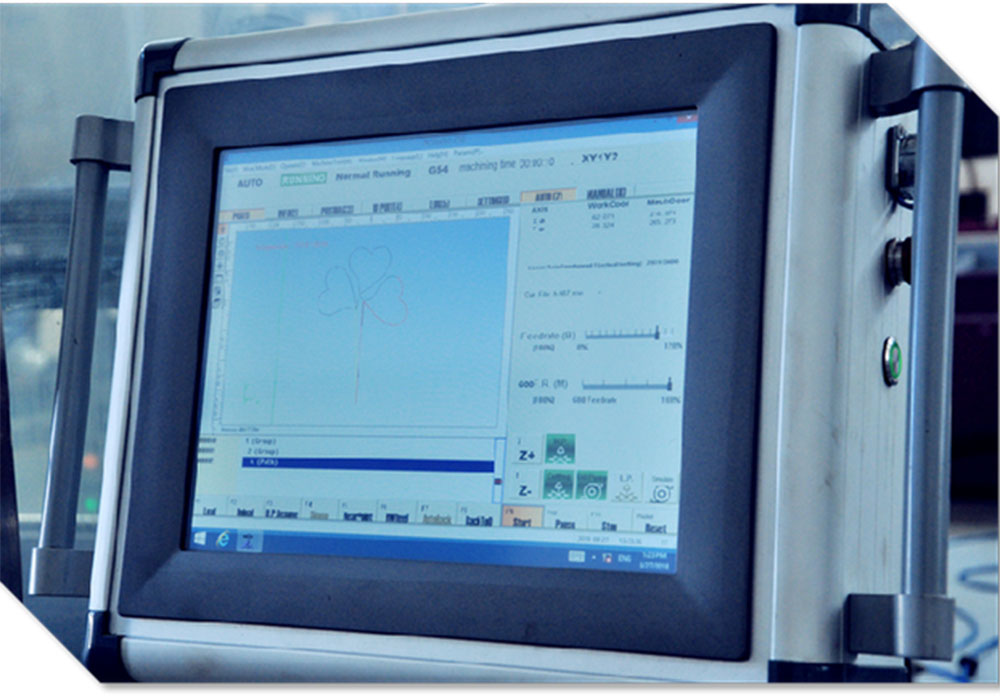

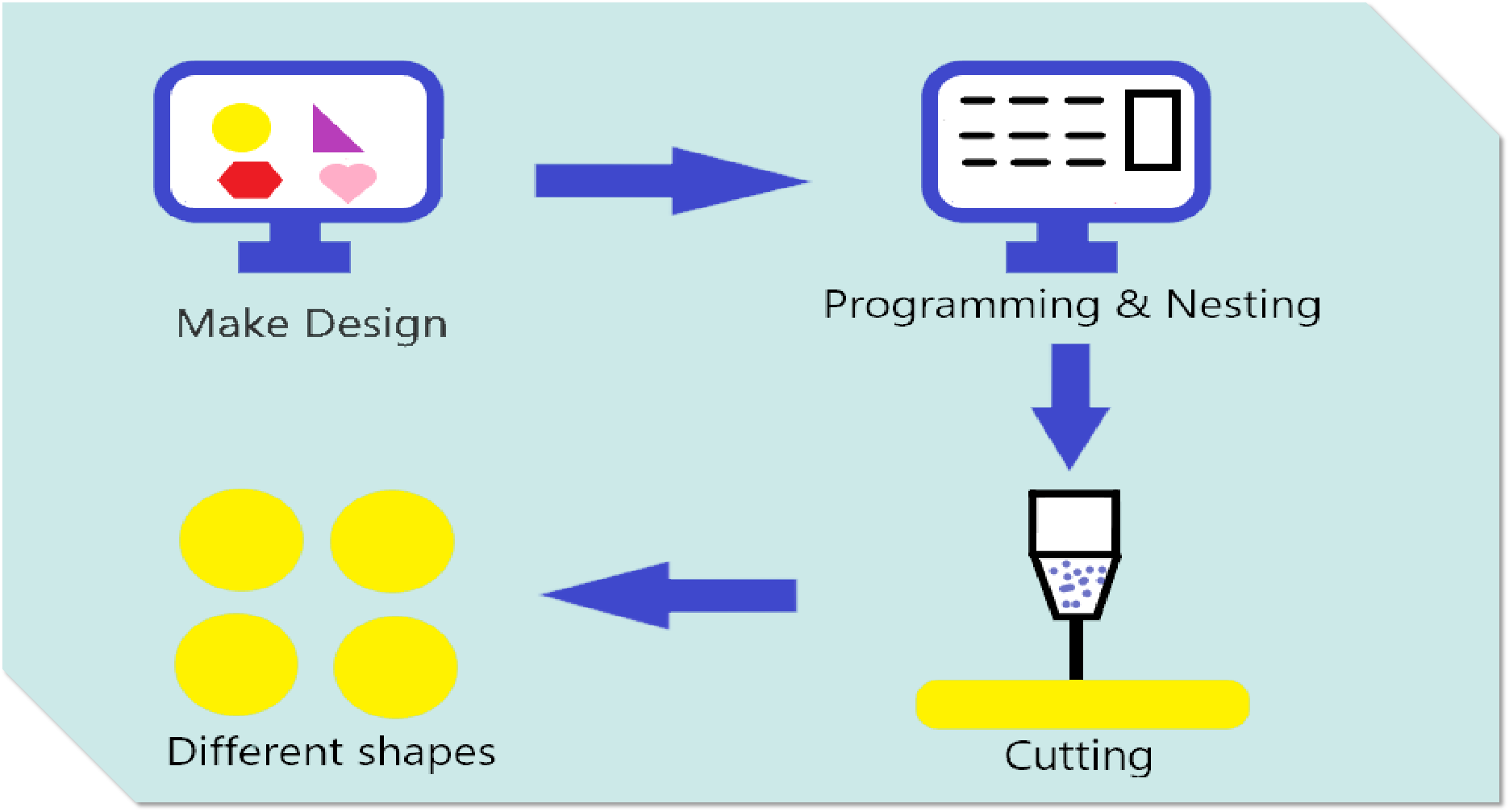

It is easy to obtain the processing graphics by drawing software (AuotoCAD). After the graphics or program is imported into the computer through USB-disk or internet, the pre-set program can be selected on the touch screen to obtain various processing shapes without any molds and tools. The operation is simple and the efficiency is high.

High productivity,save time

The quality of cutting depends on the type, temperature and cutting speed of the product. The average cutting speed is about 3-5m/min, when cutting mousse or biscuits, the speed can reach 10m/min.The biggest advantage of waterjet cutting is the time savings using pure water as a food cutting solution. Since no knife blades are ever used, there is no downtime changing out or sharpening dull blades.

Water jet cutting can be used not only for all kinds of pastry, pizza, biscuits, moss, but also for meat, fish,vegetables and frozen food cutting etc.

Safety & Clean

Cutting In the process of water cutting, food is only in contact with pure water, which avoids the risk of food contamination caused by traditional cutting tools.,It will not maake heat and add any chemicals. Hygiene is unmatched in the cutting process. typically the size of the stream is a width of a human hair at speeds up to 900m per second. This small kerf width is so thin that food will not be compressed or washed out. No need for mold,

Easy Operating

It is easy to obtain the processing graphics by drawing software (AuotoCAD). After the graphics or program is imported into the computer through USB-disk or internet, the pre-set program can be selected on the touch screen to obtain various processing shapes without any molds and tools. The operation is simple and the efficiency is high.

High productivity,save time

The quality of cutting depends on the type, temperature and cutting speed of the product. The average cutting speed is about 3-5m/min, when cutting mousse or biscuits, the speed can reach 10m/min.The biggest advantage of waterjet cutting is the time savings using pure water as a food cutting solution. Since no knife blades are ever used, there is no downtime changing out or sharpening dull blades.

Details of Table

CNC Controller

Working Flow Chart

Food cutting solutions

YCWJ-0806F

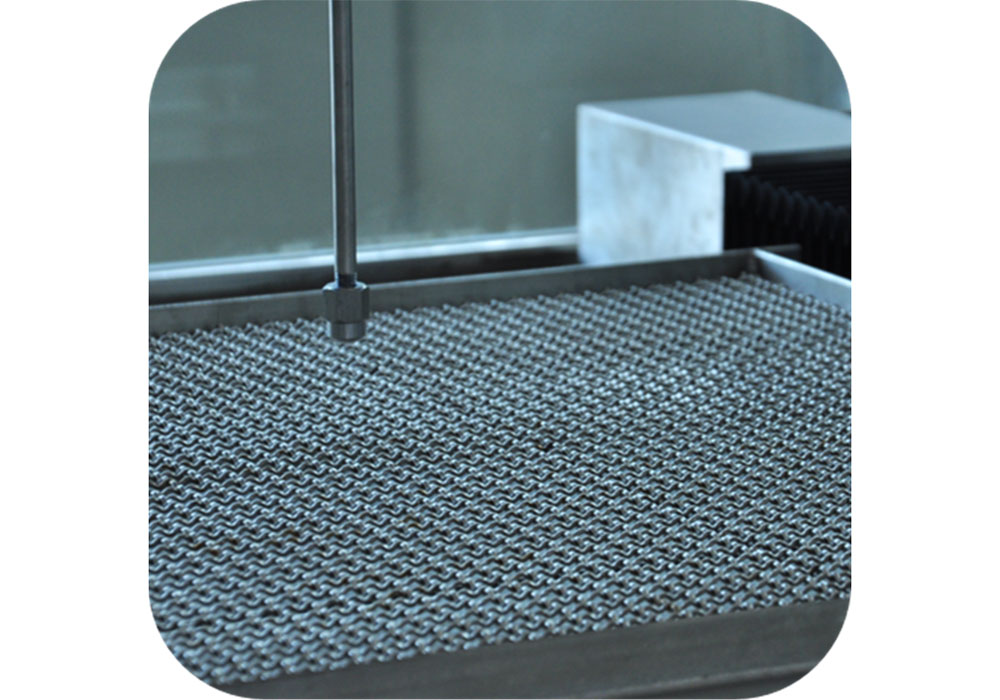

Table structure:

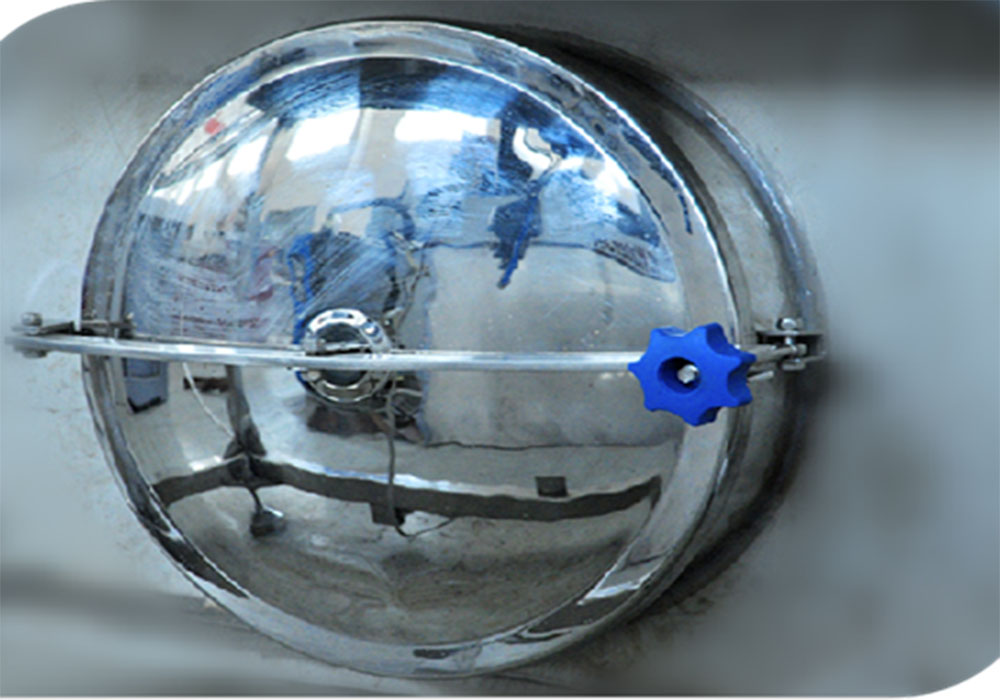

- It is manufactured with food grade stainless steel,hygienic and reliable. Totally enclosed glass cutting space, clean and dust-free. we can clearly watch the cutting process under the LED lights .

- It will be shut down if open the window, it's safe and smart.

- The SS collecting tank can concentrate the residue and the waste water after cutting.

- Movable cleaning window is simple and convenient to operate.

- Only water cutting head is easy to maintenance.

- With AC servo system, the accuracy is higher.

- Linear guide and ball screw module is durable.

- Effective cutting size:800mm*600mm*200mm

- Maximum idle speed:8000mm/min

- Maximum cutting speed:5000mm/min

Dimension:1800×1450×1900mm

Weight:800kg

- It is manufactured with food grade stainless steel,hygienic and reliable. Totally enclosed glass cutting space, clean and dust-free. we can clearly watch the cutting process under the LED lights .

- It will be shut down if open the window, it's safe and smart.

- The SS collecting tank can concentrate the residue and the waste water after cutting.

- Movable cleaning window is simple and convenient to operate.

- Only water cutting head is easy to maintenance.

- With AC servo system, the accuracy is higher.

- Linear guide and ball screw module is durable.

- Effective cutting size:800mm*600mm*200mm

- Maximum idle speed:8000mm/min

- Maximum cutting speed:5000mm/min

Dimension:1800×1450×1900mm

Weight:800kg

Smart and clean

All stainless steel manufacturing

Easy of Adjustment

Core Component Options

Featuring a low noise, no pollution, high precision and high reliability

Max 5 cutting head

This Max 5 waterjet cutter can cut any angle within ±45°,it solves the traditional problem of water cutting inclination,and achieves 2D/3D cutting easily.

Dynamic 5 cutting head

Our Dynamic 5 water jet cutting machine can ensure the accuracy of vertical cutting section by compensating the 10°cutting angle,without reducing the cuttiong speed.

Multi-head

Double or multiple cutting heads can perform the cutting task with the same track at the same time to improve efficiency greatly.

This Max 5 waterjet cutter can cut any angle within ±45°,it solves the traditional problem of water cutting inclination,and achieves 2D/3D cutting easily.

Dynamic 5 cutting head

Our Dynamic 5 water jet cutting machine can ensure the accuracy of vertical cutting section by compensating the 10°cutting angle,without reducing the cuttiong speed.

Multi-head

Double or multiple cutting heads can perform the cutting task with the same track at the same time to improve efficiency greatly.

Unique design of this water jet cutting machine makes the installation and the maintenance easier.Stable working pressure to ensure the working efficiency.

1.YC pumps 40hp/50hp/100hp2.Hypertherm

Optional Functions

-

Automotive Interior

-

Stone Processing

-

Glass Processing

-

Compound Material Processing

-

Metal Processing

-

Food (Pure Water Cutting)