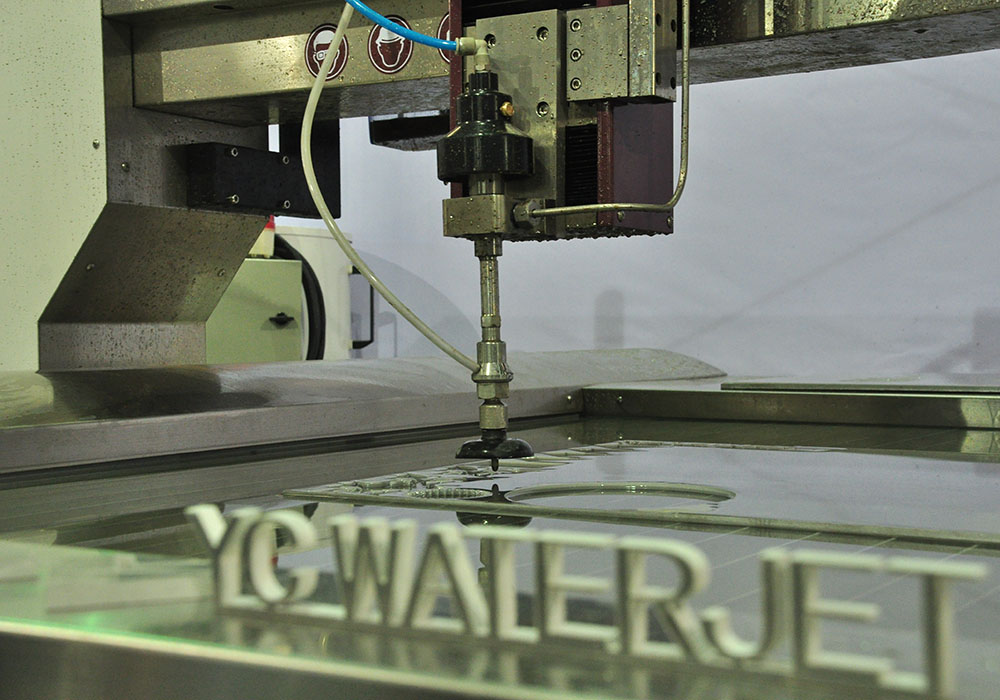

Structure features of Cnc Waterjet Machine:

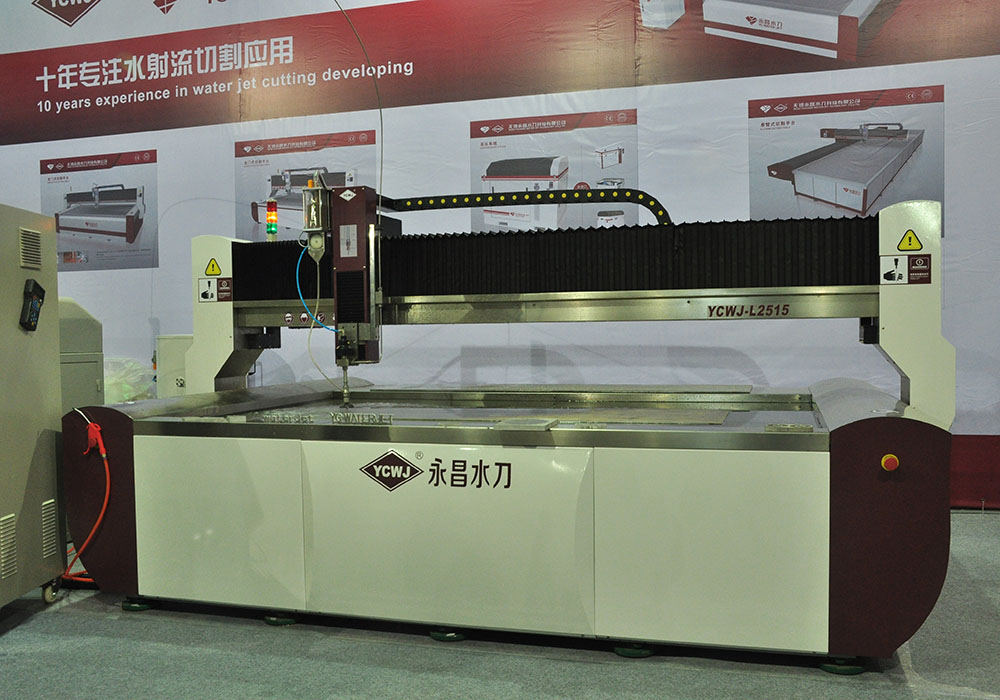

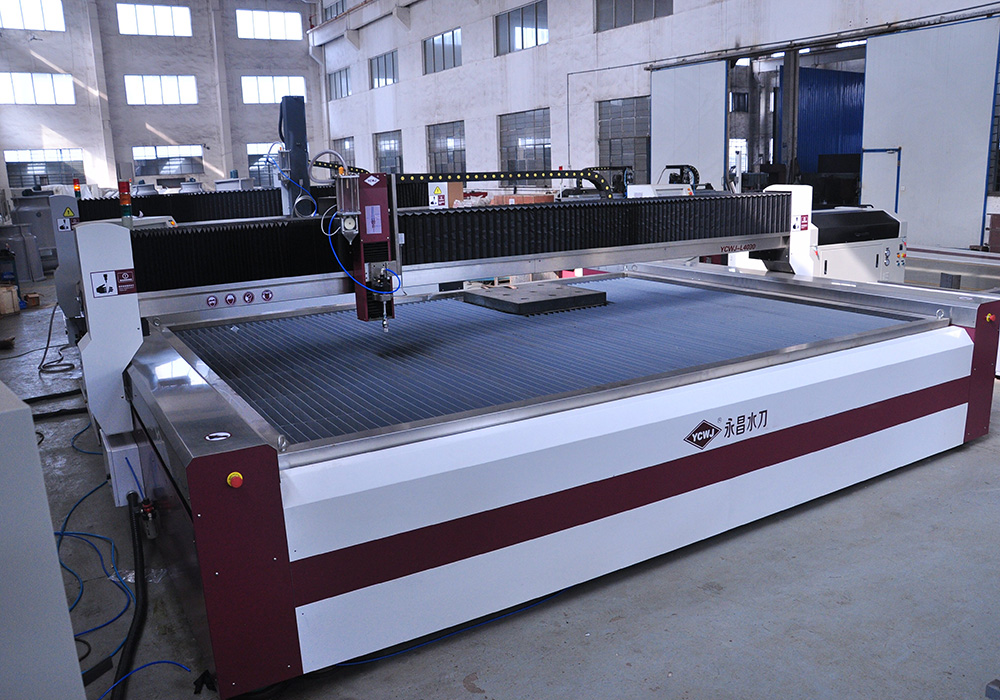

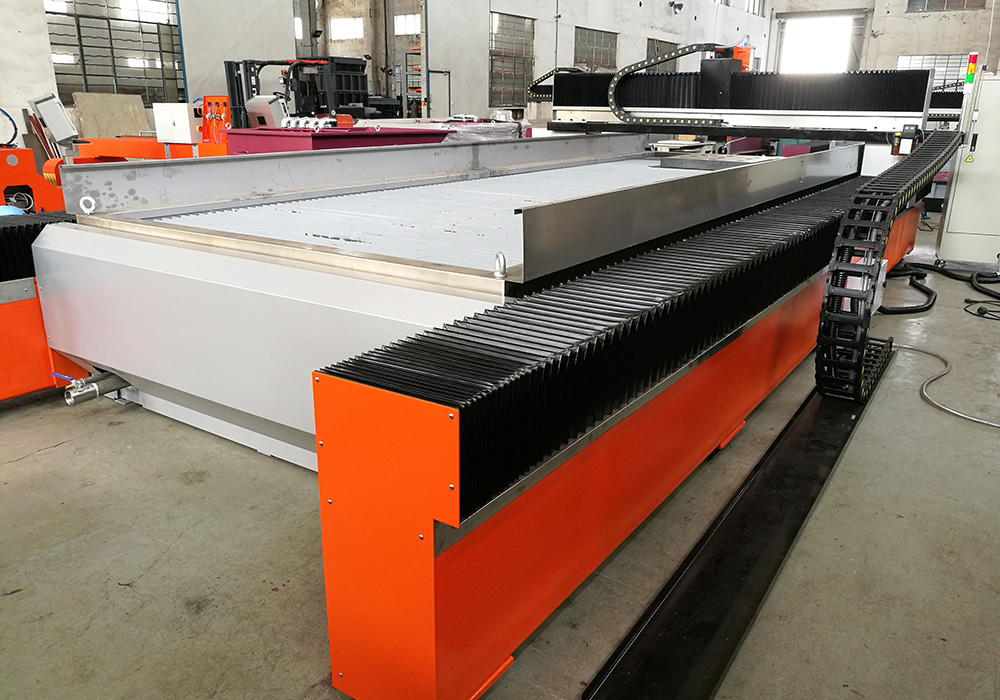

Superior precision and stability are guaranteed by the casting beam and base frame of Y-axis.Lathe bed and water tank are non-detachable, After the annealing treatment of whole machine table (to eliminate the stress of 95%), it is much better than the VSR (to eliminate the stress is 35%),It can ensure the accuracy and stability in long time.

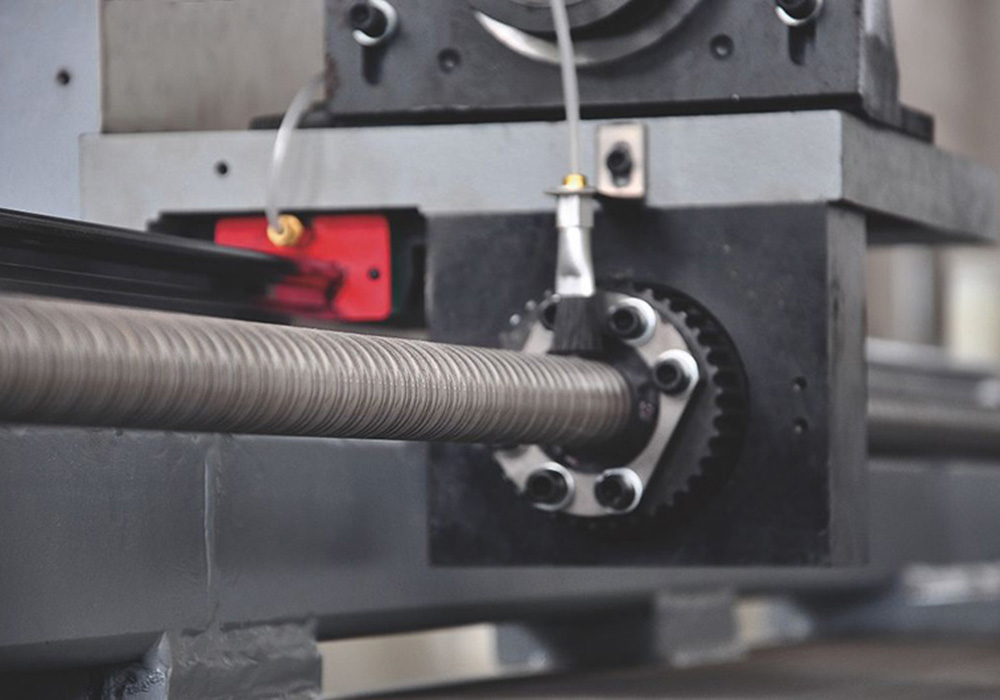

X-axis and Y-axis adopt high-precision ball screw and guide linear rail.

This split gantry type cnc water jet cutting machine is configured with double cutting heads .

|

CNC water Jet Cutting machine(L=Gantry type) |

|||||||

|

Parameters |

Unit |

YCWJ-L1010 |

YCWJ-L1515 |

YCWJ-L2015 |

YCWJ-L2515 |

YCWJ-L3015 |

|

|

Efficient Cutting area |

mm |

1000*1000 |

1500*1500 |

2000*1500 |

2500*1500 |

3000*1500 |

|

|

Axis travel |

X |

mm |

1000 |

1500 |

2000 |

2500 |

3000 |

|

|

Y |

mm |

1000 |

1500 |

1500 |

1500 |

1500 |

|

|

Z |

mm |

150-180 |

150-180 |

150-180 |

150-180 |

150-180 |

|

Cutting accuracy |

mm |

+/-0.1 |

|||||

|

Positioning accuracy |

mm |

+/-0.02 |

|||||

|

X,Y dry-run speed |

m/min |

0-15 (if need 30m/min speed,we can do as request ) |

|||||

|

Cutting speed |

m/min |

as to detail material and thickness |

|||||

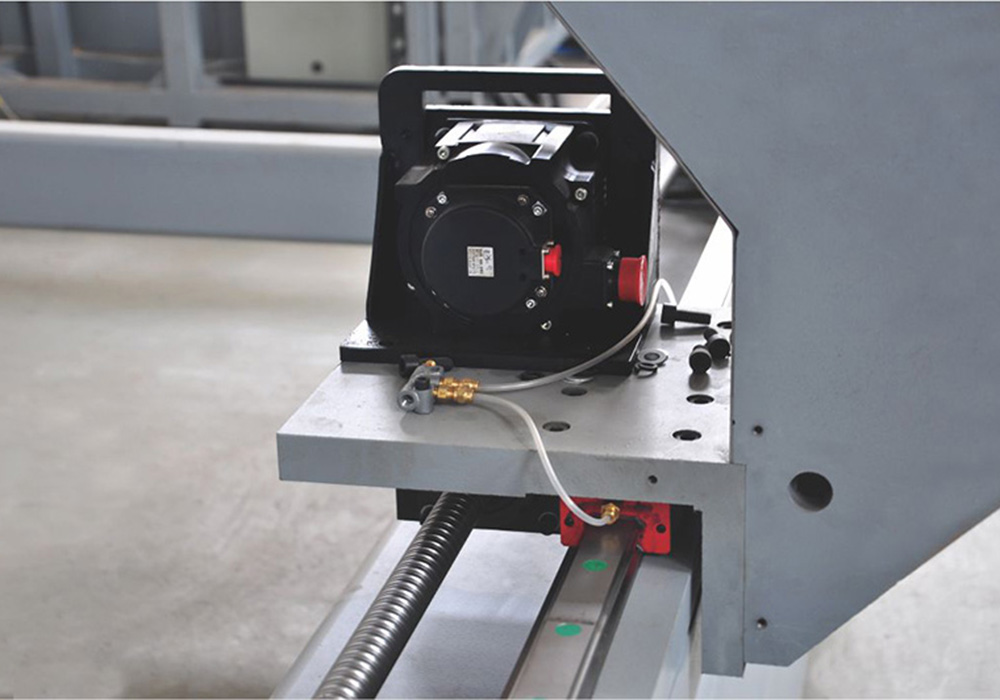

Superior precision and stability are guaranteed by the casting beam and base frame of Y-axis.

Lathe bed and water tank are detachable, which are designed to reduce the pressure from water with sands and machined parts to moving parts.

The base of Y-axis is overall manufacturing, It’s convenient for disassembly, transportation and assembly.

X-axis and Y-axis adopt high-precision ball screw and guide linear rail.

|

CNC water Jet Cutting Machine(L=Gantry type) |

||||||

|

Parameters |

Unit |

YCWJ-L3020 |

YCWJ-L4020 |

YCWJ-L3040 |

YCWJ-L2060 |

|

|

Efficient Cutting area |

mm |

3000*2000 |

4000*2000 |

3000*4000 |

2000*6000 |

|

|

Axis travel |

X |

mm |

3000 |

4000 |

3000 |

2000 |

|

|

Y |

mm |

2000 |

2000 |

4000 |

6000 |

|

|

Z |

mm |

150-180 |

150-180 |

150-180 |

150-180 |

|

Cutting accuracy |

mm |

+/-0.1 |

||||

|

Positioning accuracy |

mm |

+/-0.02 |

||||

|

X,Y dry-run speed |

m/min |

0-15 (if need 30m/min speed,we can do as request ) |

||||

|

Cutting speed |

m/min |

as to detail material and thickness |

||||

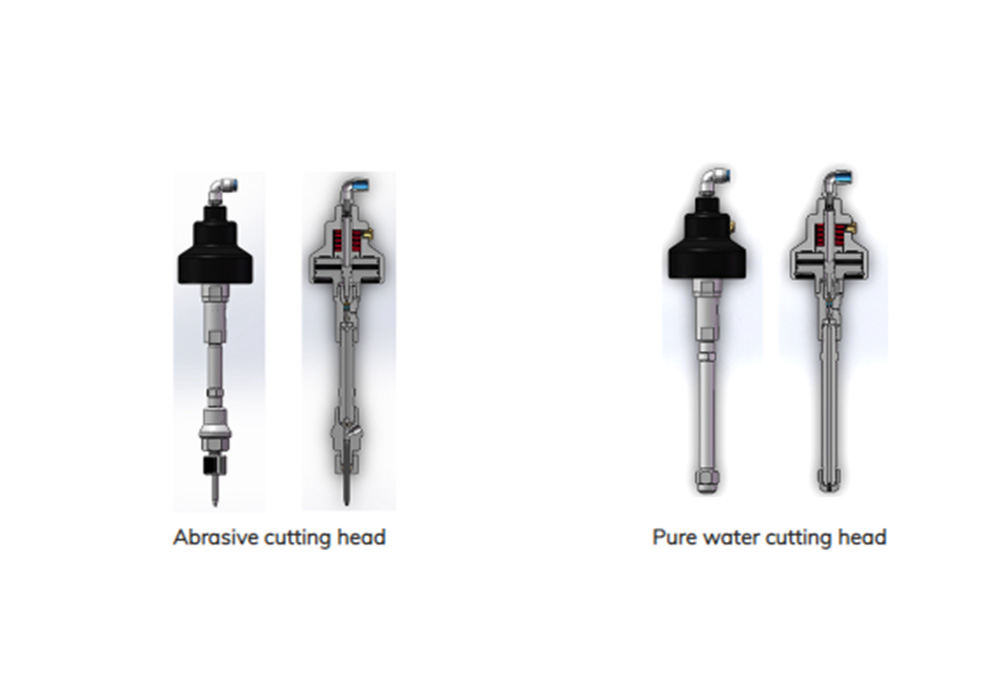

Ultra high pressure cnc water jet cutting is mainly divided into abrasive cutting and only water cutting(Including pure water cutting). Therefore, the cutting head is also divided into abrasive waterjet cutting head and pure waterjet cutting head.

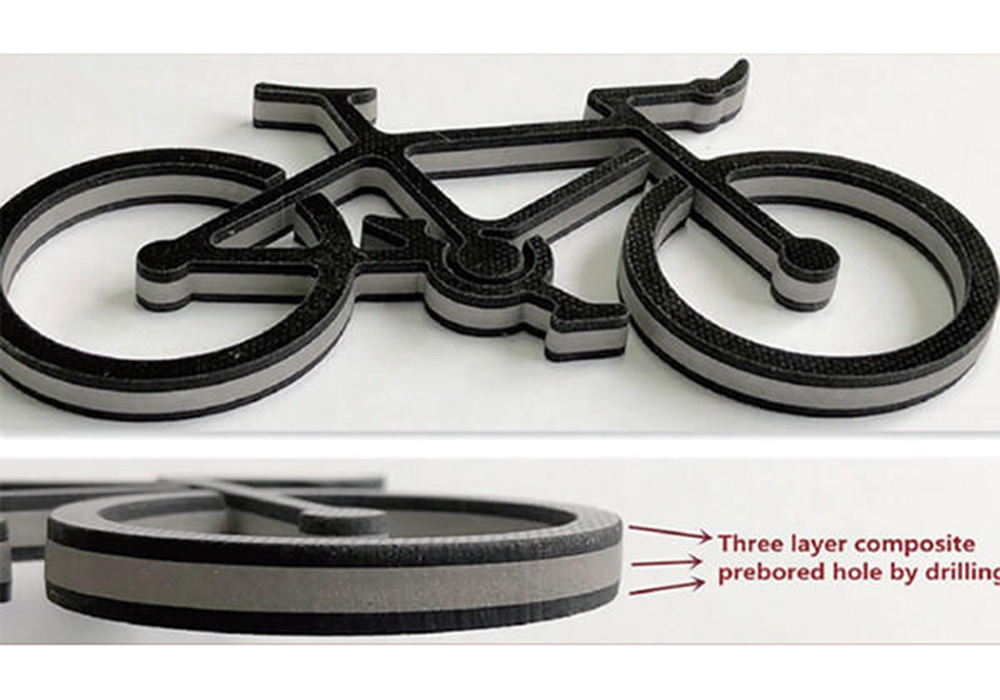

Abrasive cnc waterjet cutting is mainly used for cutting metal (such as carbon steel, stainless steel, etc.), nonferrous metal (such as copper, aluminum, titanium alloy, magnesium alloy, etc.), stone, glass, large thickness composite materials (such as carbon fiber, glass fiber) and so on.

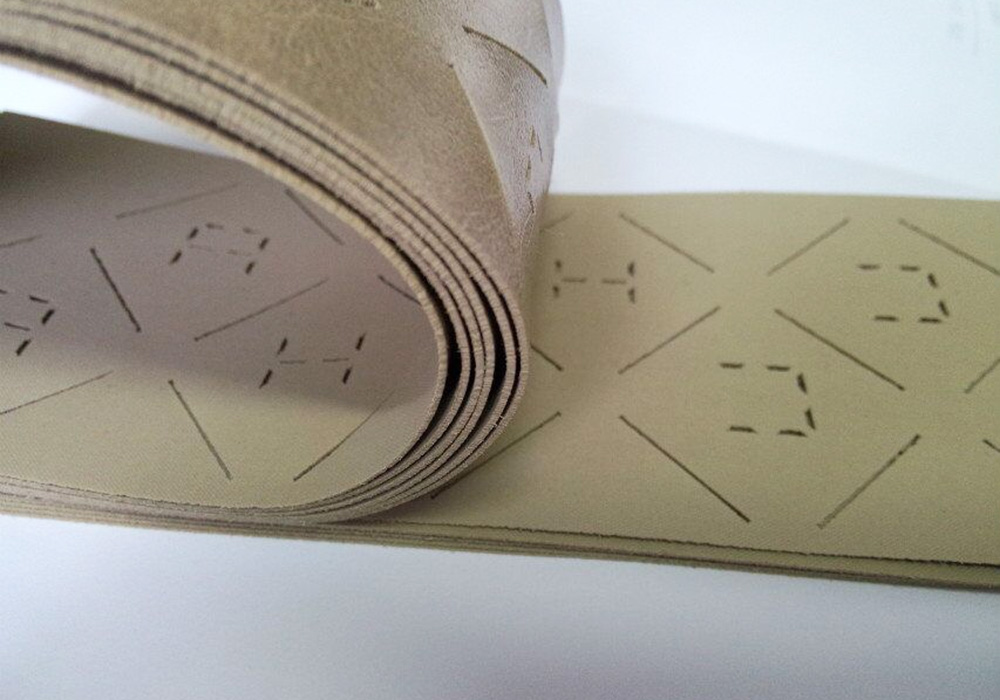

Only water cutting is mainly used for cutting rubber, foam, cloth, paper, rock wool, food (pure waterjet cutting)and so on.

Featuring a low noise, no pollution, high precision and high reliability

This Max 5 cnc waterjet cutting machine can cut any angle within ±45°,it solves the traditional problem of water cutting inclination,and achieves 2D/3D cutting easily.

Dynamic 5 cutting head

Our Dynamic 5 cnc waterjet cutting machine can ensure the accuracy of vertical cutting section by compensating the 10°cutting angle,without reducing the cuttiong speed.

Multi-head

Double or multiple waterjet cutting head can perform the cutting task with the same track at the same time to improve efficiency greatly.

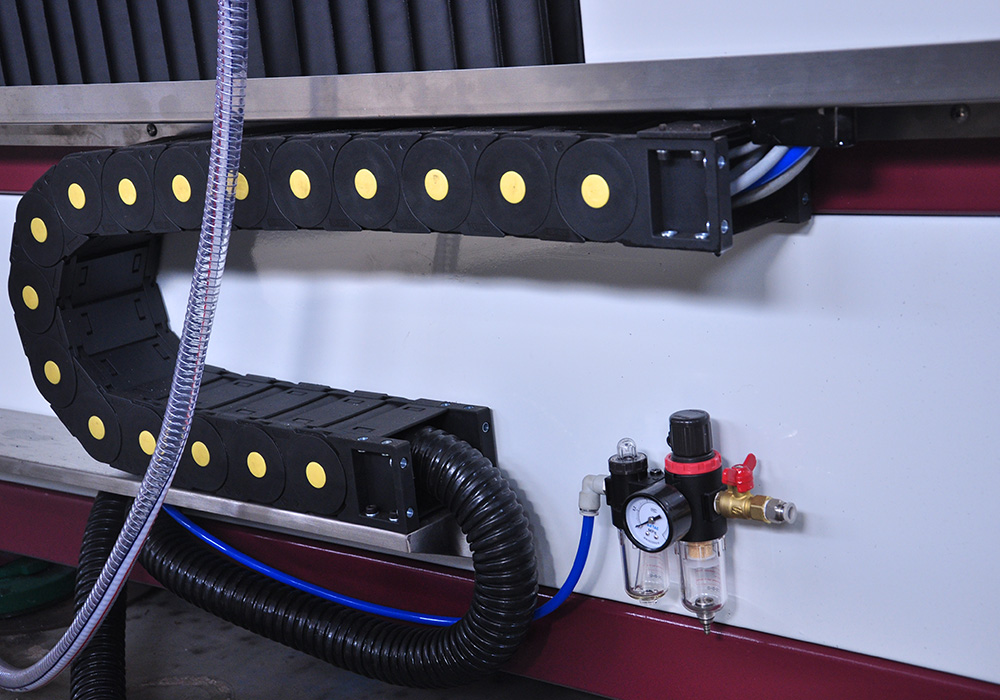

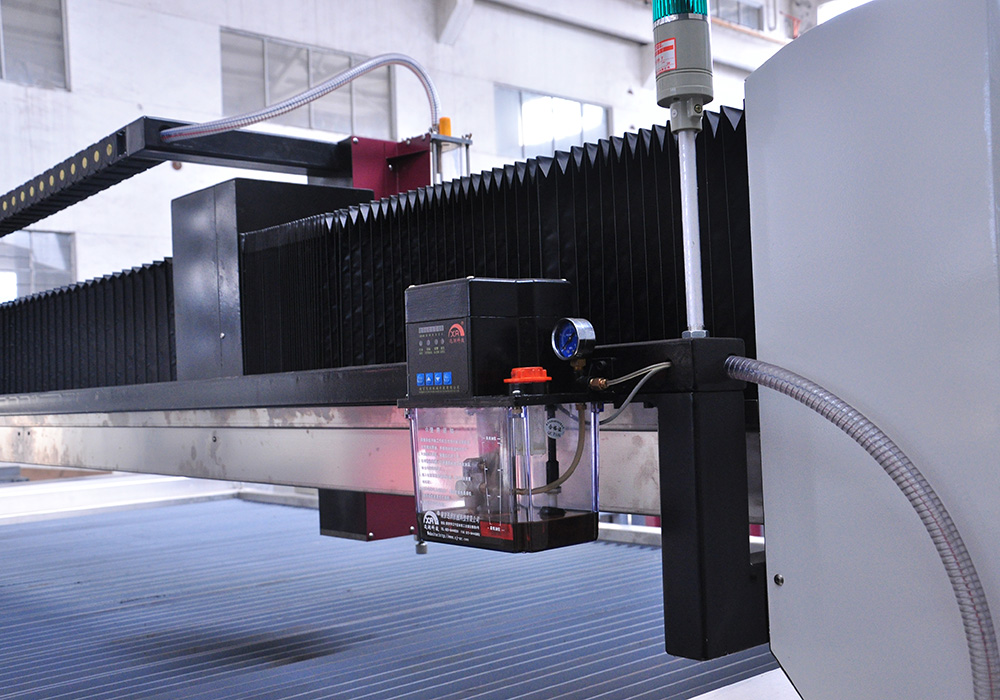

Unique design of this cnc water jet cutting machine makes the installation and the maintenance easier.Stable working pressure to ensure the working efficiency.

1.YC pumps 40hp/50hp/100hp2.Hypertherm

-

Automotive Interior

-

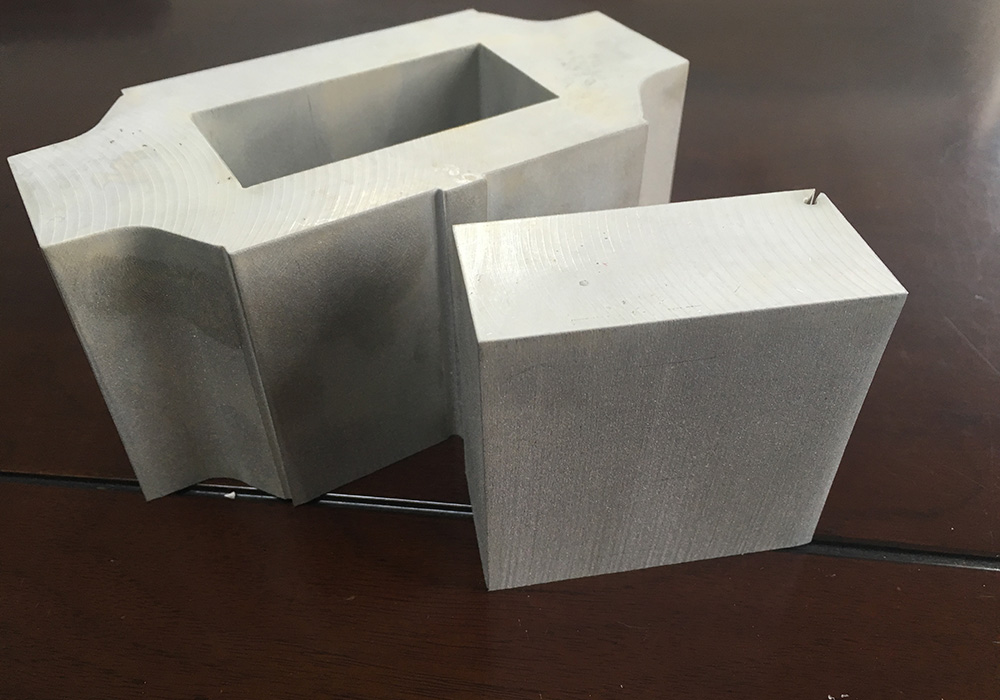

Stone Processing

-

Glass Processing

-

Compound Material Processing

-

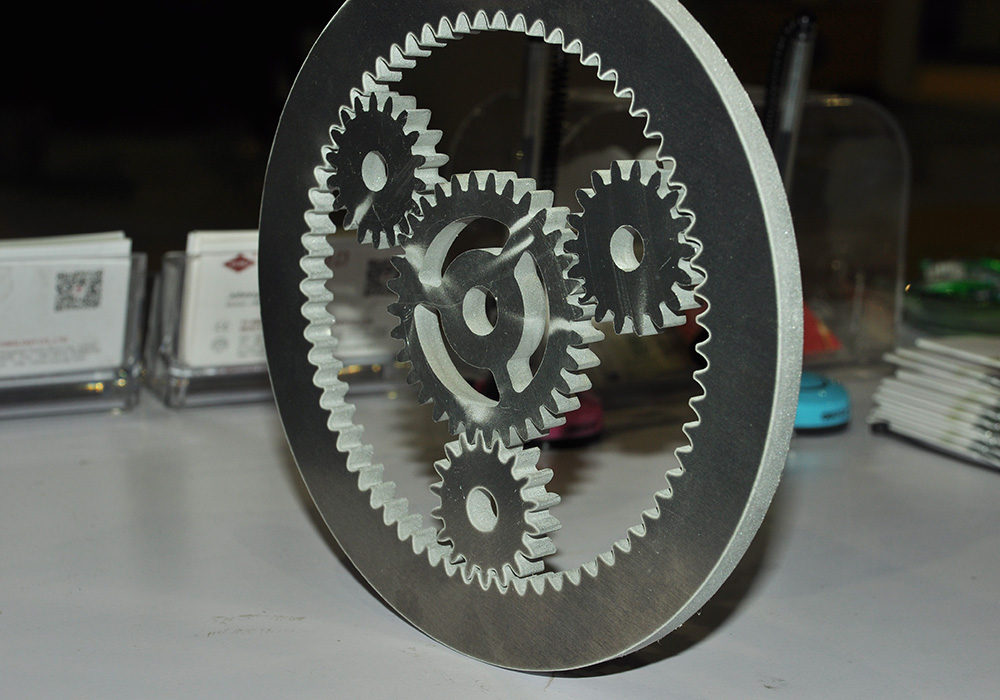

Metal Processing

-

Food (Pure Water Cutting)

-

-